As governments around the world push to reduce greenhouse gas emissions from internal combustion engine (ICE) vehicles, original equipment manufacturers (Oems) are redesigning mechanical systems to be electronically controlled. High levels of system connectivity and intelligent technology are making autonomous vehicles a reality, so there is a growing demand for electronics and software algorithms to comply with various safety requirements, including the International Organization for Standardization (ISO) 26262.

Sensors, especially Angle sensors, are indispensable in systems that need to meet functional safety standards. It helps to monitor and provide the torque and Angle information that is necessary to efficiently drive or operate various automotive systems.

Designing EPS system

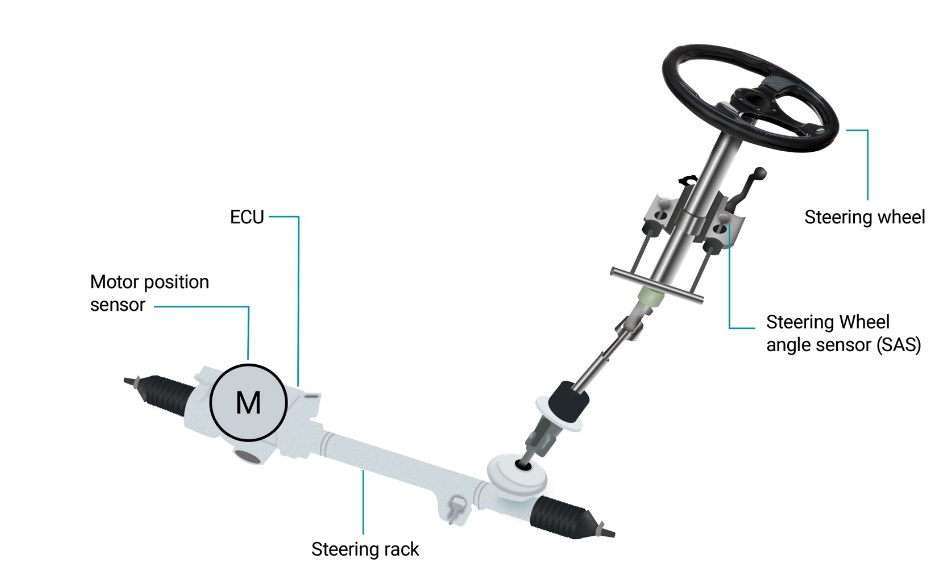

The electric power steering system (EPS) consists of a steering column, an electronically controlled steering motor and an electronic induction and control mechanism. When the driver turns the steering wheel, the steering is assisted by a motor (usually a brushless DC motor), which replaces traditional mechanical and hydraulic systems.

The benefits of EPS systems include faster and smarter operation, reduced CO2 emissions, improved fuel efficiency and enhanced user experience. The driver provides system input at the steering wheel interface. Sensors detect the position of the motor shaft and the rotation of the steering wheel and send the data to the electronic control unit (ECU). Figure 1 highlights the basic elements of an EPS system.

Figure 1: EPS system

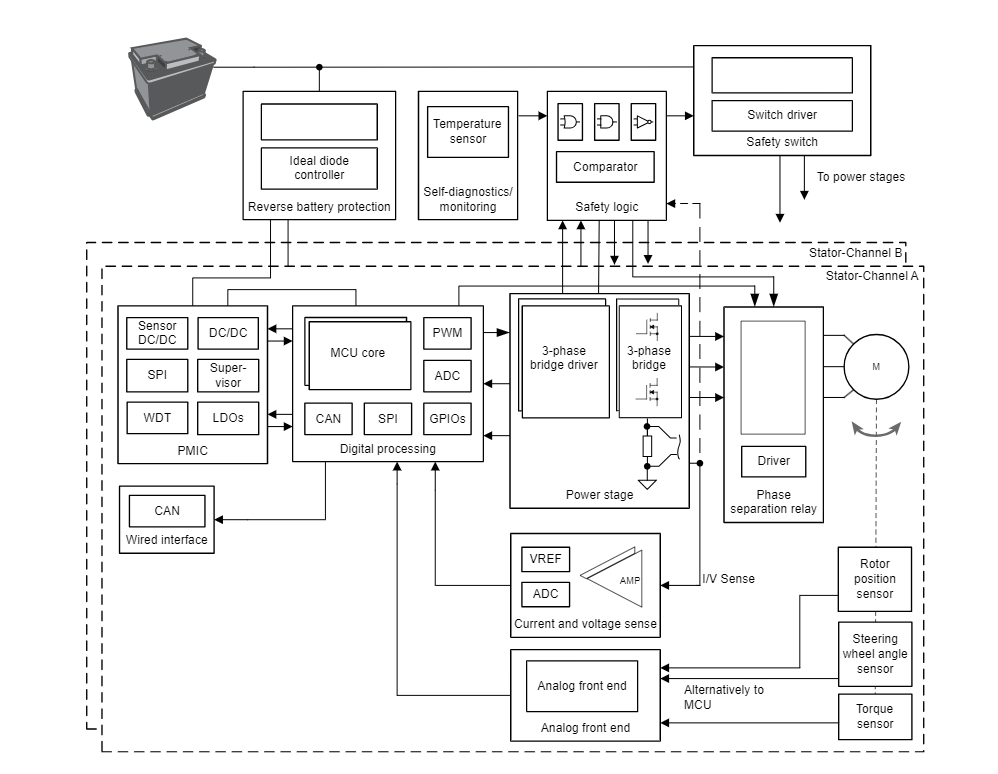

The components needed to design an EPS system include microcontrollers, sensors, power supplies, motor drivers, and transistors. These components are essential for efficient system communication and operation. As shown in Figure 2, the controller LAN is the bus standard for connecting vehicle ECUs.

Figure 2: Block diagram of EPS system

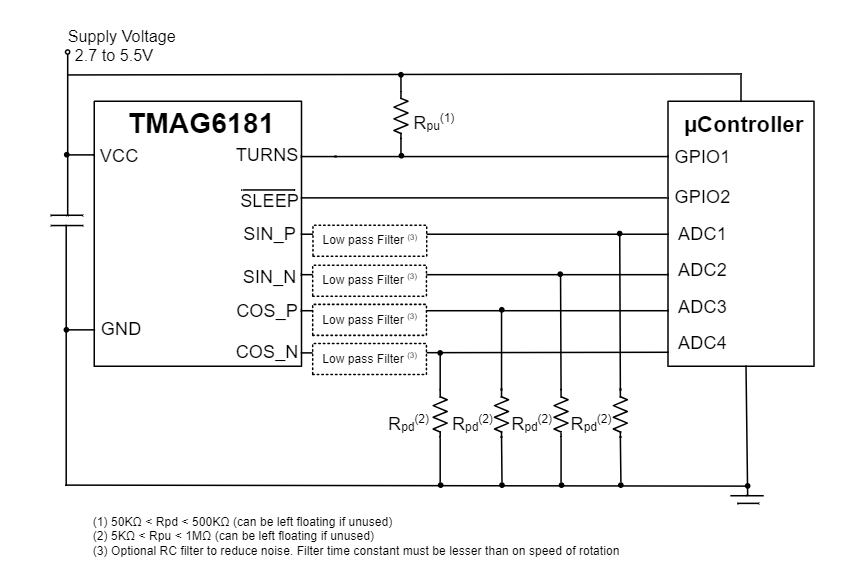

Texas Instruments' (TI) TMAG6181-Q1 is an anisotropic reluctance(AMR) Angle sensor. It has an integrated signal conditioning amplifier capable of providing differential sine and cosine analog outputs related to the direction of the applied planar magnetic field.

The TMAG6181-Q1 has a latency of less than 2µs and an Angle error of just 0.4 degrees, helping to greatly improve system performance and efficiency. The sensor's integrated turn counter tracks motor speeds up to 32,000 revolutions per minute (rpm) in normal operation mode and up to 8,000 rpm in low-power mode. It also supports a wide range of device and system-level diagnostics to detect, monitor, and report faults during device operation. For example, in sleep or fault mode, the output of the TMAG6181-Q1 AMR sensor will enter a high impedance state. It is recommended to use a pull-down or pull-up resistor to ensure that the microcontroller can detect faults.

To process the AMR output signal and extract the angular position of the EPS motor or steering wheel, an external microcontroller is usually required. The AMR Angle sensor in the TMAG6181-Q1 can be used in single-ended or differential output modes; The latter mode eliminates common-mode interference in the system. The differential output sine and cosine signals from the AMR sensor are proportional to the Angle of the applied magnetic field. The output voltage of the AMR sensor is proportional to the supply voltage to ensure that the external ADC can reference the supply voltage.

Figure 3 shows a typical application diagram where the differential output signals SIN_P, SIN_N, COS_P, and COS_N are connected to four single-ended analog-to-digital converters in an external microcontroller that communicates with the ECU in an EPS system.

Figure 3: TMAG6181-Q1 in single-ended output mode

If available, a differential ADC is recommended because it improves reliability. To achieve high precision, load capacitors and resistors must match each other. The TMAG6181-Q1 can drive capacitive loads up to 10nF directly on the AMR output pin, and drive resistive loads with pull and fill currents up to 1mA. This enables the smooth and reliable operation of the EPS system.

To simplify compliance, ISO 26262 system design documentation is available for TMAG6181-Q1, with an automotive safety integrity rating up to Level B.

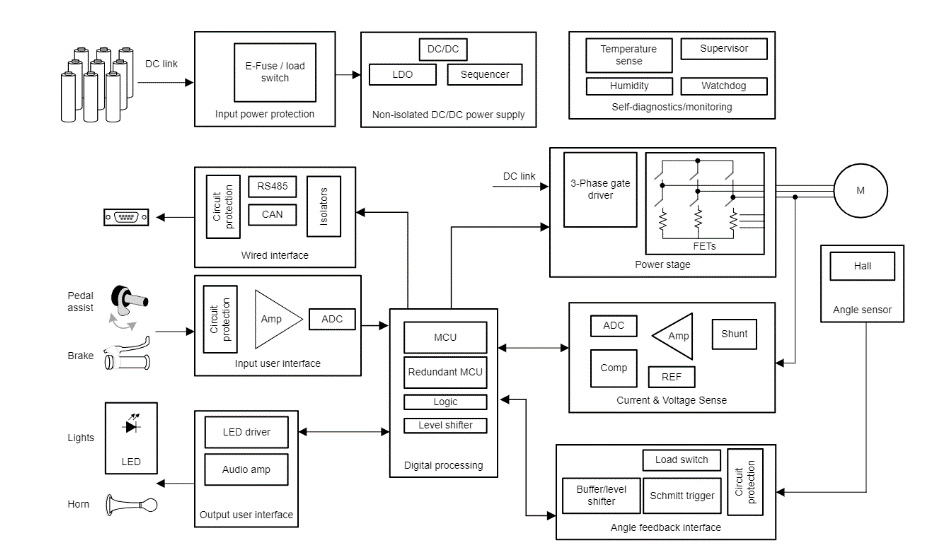

Design electric bicycle and electric scooter systems

An e-bike is a bike that contains five key components: a motor, a battery, controls, sensors and a display. The motor is an integral part of an e-bike and can be used to provide the additional power required during pedaling. As shown in the block diagram in Figure 4, Angle sensors are needed to efficiently and reliably rotate the motor (which can be mounted front, center, or rear).

Electric scooters are converted from gas driven scooters to electric scooters. Its motor drive system design is very similar to that of an electric bike, except it's not as complicated. Electric scooter designs only need to power the motor when the accelerator is pressed down, but electric bike designs must also monitor the rider's pedal power to determine the power supply to the motor. Different regions require e-bikes and e-scooters to achieve a similar level of safety as the automotive industry.

Figure 4 highlights the components needed to develop an e-bike system. The Angle sensor provides Angle feedback, which is then calculated by a microcontroller to rotate the motor efficiently and reliably. AMR sensors are typically limited to 180 degrees, but the TMAG6181-Q1 adds two separate Hall effect sensor outputs in the X and Y axes, extending the sensor's angular range to 360 degrees.

Figure 4: Block diagram of electric bicycle

Conclusion

Today's cars and e-bikes contain multiple ECUs for driving and controlling advanced functions. Designing EPS systems, e-bikes or e-scooters requires precise ECU control for efficient and reliable operation. The TMAG6181-Q1 enables faster and more precise motor control, helping to improve system performance.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.