Along with power generation and transmission, storing energy obtained from intermittent sources such as solar and wind is one of the top three challenges for renewable energy. Methods for storage include harnessing potential energy based on gravity (lakes and DAMS, weightlifting); Kinetic energy using flywheel; Thermochemical system of phase change materials including molten salt; Electrolysis provides hydrogen; Pressure through compressed air; And, of course, electrochemical storage via batteries.

The battery system, formally called a battery energy storage system (BESS), is popular due to its modularity in sizing, along with the availability of both new and even used batteries reclaimed from electric vehicles and other sources. They are also popular because many of the critical support electronics such inverters, protection circuits, and connectors are widely available.

However, for various reasons, BESS has its limitations and is not a solution for all installations. These include battery degradation caused by charge and discharge cycles; Complexity of battery management algorithms; And the risks associated with some battery chemicals (fire and chemistry).

Now, some startups are looking at a radically different principle for capturing usable energy and then releasing it when needed: thermal batteries. These zero-emission devices store the accumulated energy in the form of heat, the most basic form of heat. While heat has been used to accomplish this function through hot water or molten salt, the latest methods are much more intense.

For example, Antora Energy (Sunnyvale, CA) is field-testing storage units that use carbon (graphite) blocks in a thermal-insulator container roughly the size of a truck trailer. The effort is funded with venture capital from various government grants, investment company BlackRock, Inc., renewable energy giant NextEra Energy, and Bill Gates’s Breakthrough Energy Ventures. A prototype unit was set up in 2023 and is being field tested, Figure 1.

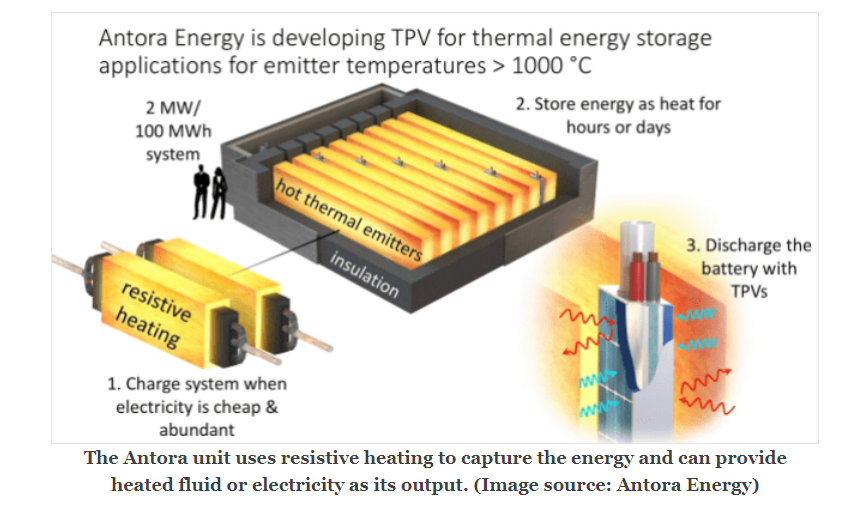

They use carbon blocks because they can store large quantities of heat at 1000°C to 2000°C (~1275K to ~2275K), and their heat-storage capacity actually increases as they get hotter. The energy density of their heat radiation is defined by Stefan’s law and is proportional to the fourth power of the temperature (open that dusty physics book and review “blackbody radiation” if you need to).

Antora’s design captures available electricity as heat using basic resistive heating, and then extracts that energy in two ways. It can be used directly for some of the many industrial processes that require heat for production, or use thermophotovoltaic (TPV) technology to convert the stored heat directly into electricity with no moving parts, Figure 2. Elimination of the need for moving air or fluid to transfer energy should increase reliability and reduce costs.

[Again, referring to your physics books, TPV conversion is a direct-conversion process of transforming heat energy into electricity via photons. A basic thermophotovoltaic system consists of a hot object emitting thermal radiation and a photovoltaic cell similar to a solar cell but tuned to the spectrum being emitted from the hot object.]

The carbon-block technology has some other important benefits, including the absence of environmental hazards or even explosive substances. The system should be safe, reliable, compact, silent, and easily site-able, and if something fails, you’ve got a block of super-hot carbon that can cool off with minimal negative consequences.

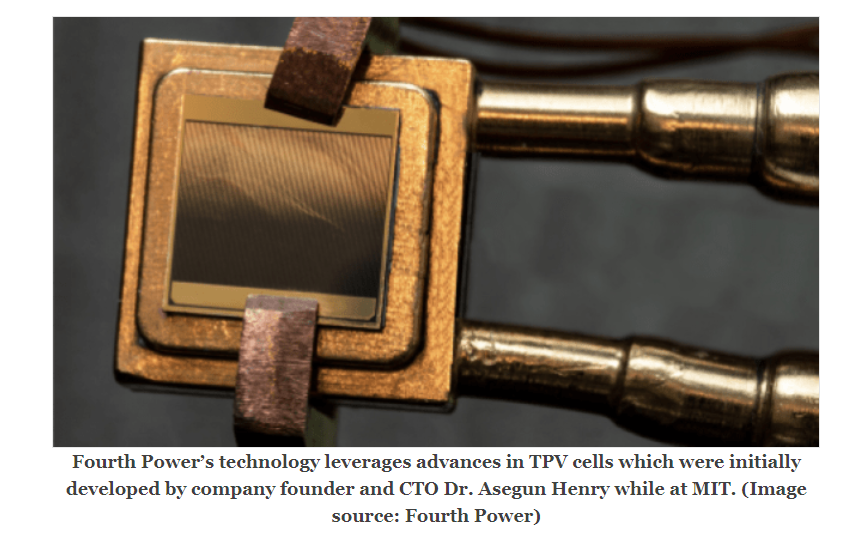

Another startup developing intense-heat storage is Fourth Power, Inc. based in Cambridge, MA, which has also received significant venture and other funding. Like Antora, they use stacks of carbon blocks at around 2,400°C, but they are instead heated by molten tin, which itself is heated using electricity from solar panels or wind turbines.

To create electrical power, TPV devices absorb the thermal energy that those stacks emit. The system’s ongoing loss, which is somewhat analogous to self-discharge of a chemical battery, is only about 1% of its capacity. The graphite blocks are sited in a chamber filled with argon to keep corrosive oxygen out.

Fourth Power claims three breakthroughs were needed to make their approach practical: a centrifugal pump and plumbing system made entirely of graphite to handle liquids at extreme temperatures; TPV cells which are over 40% efficient; and a way to keep those PV cells clean when they’re in the presence of the superheated materials (a degrading phenomenon called emitter deposition).

As with the Antora system, the Fourth Power approach is safe and there is no risk of thermal runaway as the system is chemically inert. Further, the liquid tin is completely shielded and contained in the plumbing system; if there was a leak, the tin would freeze in the insulation or as soon as it touches the concrete floor of the enclosure.

It’s safe to assume that the investors in these systems have done considerable technical and costing “due diligence.” Fourth Power maintains their cost is about one-tenth that of than lithium-ion batteries ($25/kWh vs. $330/kWh); Antora cites comparable figures.

It will be interesting to see how these systems work out in the field tests. Obviously, despite their conceptual elegance and simplicity, there are countless engineering and implementation challenges to be identified, analyzed, assessed, and overcome. All the sophisticated modeling, simulation, possible worst-case scenarios, and more can’t anticipate the real-world complications or unanticipated “stuff” that still happens.

It’s especially difficult with energy-related projects because energy, almost by definition, does not like to managed, stored, corralled, and channeled. There are many inefficiencies that occur along the complete energy in/power out path and conversion stages, which accumulate and can turn a highly efficient core function into a very lossy overall project.

Further, some aspects of the energy triad (sourcing, storage, transmission) get simpler or at least less costly per watt as you scale up, due to economies of scale and other technical factors. On the other hand, other factors get exponentially more difficult as the energy levels, density, and footprint increase. These two dynamics are in continual conflict, and it will be interesting to see which aspect dominates during these field tests.

As for how these attractive energy-storage options based on intense thermal batteries will play out – it looks like we will have to stay tuned and check back later, as they say.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.