0

0

0

0

Introduction

Semiconductor power devices mainly include power diode, power triode, thyristor, MOSFET, IGBT and so on. Among them, MOSFET and IGBT belong to voltage controlled switching devices, which have the advantages of fast switching speed, easy driving and low loss. The full name of IGBT is an insulated gate type power tube, which is a composite full-controlled voltage-driven semiconductor power device composed of bipolar triode (BJT) and MOSFET, and has the advantages of high input impedance of MOSFET and low on-voltage drop of BJT. With the rise of new energy vehicles, smart home appliances, 5G, rail transit and other industries, MOSFET and IGBT have also ushered in the spring of development.

However, in practical applications, engineers will encounter the same confusion: the selection of devices is really a headache, which we will take a look at the similarities and differences between MOSFET and IGBT, in the selection should focus on what parameters.

Similarities and differences between MOSFET and IGBT

Both MOSFETs and IGBTs are solid-state semiconductor devices integrated on a single chip of silicon, and both are voltage control devices. In addition, both IGBTs and MOSFETs have insulation between the gate and other terminals, and both devices have high input impedance. In applications, both IGBTs and MOSFETs can be used as static electronic switches.

Although they have a lot in common, there are still many differences between IGBTs and MOSFETs in terms of performance parameters and applications.

Structurally, MOSFETs and IGBTs look very similar, but they are different. An IGBT consists of an emitter, collector, and gate terminal, while a MOSFET consists of a source, drain, and gate terminal. The IGBT structure has PN junction, MOSFET does not have any PN junction.

In terms of characteristic parameters, the main difference between MOSFET and IGBT is reflected in the following 9 aspects:

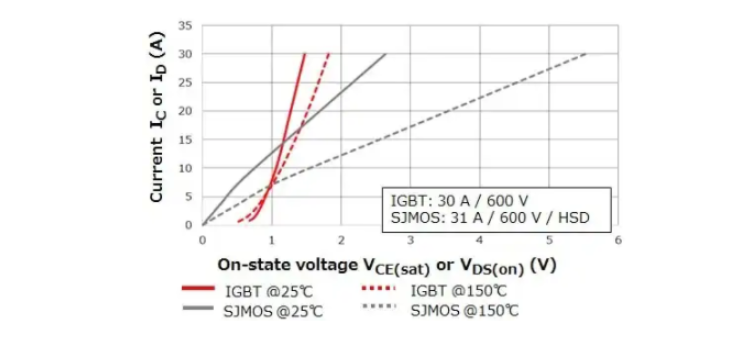

● In the low current region, the conduction of MOSFET is lower than that of IGBT, which is also its advantage. However, the forward voltage characteristic of IGBT is better than that of MOSFET in high current region. In addition, because the positive characteristics of MOSFET have a strong positive dependence on temperature, the high temperature characteristics of IGBT are better, and the on-voltage is lower than that of MOSFET.

● Igbts are suitable for conduction and control of medium to extremely high currents, while MOSFETs are suitable for conduction and control of low to moderate currents.

● IGBT is not suitable for high frequency applications, it works well at 1000 Hz. Mosfets are particularly suited for very high frequency applications, where they can operate well at megabHz frequencies.

● The switching speed of IGBT is relatively low, and the switching speed of MOSFET is very high.

● Igbts can withstand very high voltages as well as high power, and MOSFETs are only suitable for low to medium voltage applications.

● Igbts have a larger turn-off time, and MOSFETs have a smaller turn-off time.

● Igbts can handle any transient voltage and current, but when a transient voltage occurs, the operation of the MOSFET is disturbed.

● MOSFET devices are low cost and cheap, while IGBTs are still higher cost devices.

● Igbts are suitable for high power AC applications and MOSFETs for low power DC applications.

Because of these differences, MOSFET and IGBT have their own focus in application. Typically, MOSFETs are rated at about 600V, while IGBTs are rated at 1400V. From the rated voltage point of view, IGBT is mainly used for higher voltage applications. From an operating frequency perspective, IGBTs are usually used at switching frequencies below 20kHz, when they have higher switching losses than unipolar MOSFETs.

Taken together, IGBTs are preferred for applications with low frequencies (less than 20kHz), high voltages (greater than 1000V), small or narrow loads or line variations, high operating temperatures, and rated output power exceeding 5kw. Mosfets are more suitable for low voltage (less than 250V), large duty cycle and high frequency (greater than 200KHz) applications.

Figure 1: Performance comparison of different types of transistor

Key electrical parameters of MOSFET

The advantages of MOSFET make it ideal for applications with high frequency and high switching speed requirements. In switching power supplies (SMPS), the parasitic parameters of the MOSFETs are crucial, determining performance such as the conversion time, on-resistance, ringing (overshoot when switching), and backgate breakdown, which are closely related to the efficiency of the SMPS.

As a power switch, the MOSFETs chosen should have extremely low on-resistance, low input capacitance (i.e., Miller capacitance), and very high gate breakdown voltage, even high enough to handle any peak voltage generated by the inductor. In addition, the lower the parasitic inductance between the drain and the source, the better, because the low parasitic inductance can minimize the voltage peak during the switching process.

For gate driver or inverter applications, it is usually necessary to select a MOSFETs with low input capacitance (for fast switching) and high drive capability.

Key electrical parameters of IGBT

The main advantages of IGBTs are the ability to handle and conduct medium to very high voltages and currents, have very high gate insulation characteristics, and produce very low forward voltage drops during current conduction, even when surge voltages are present, the operation of IGBTs will not be disturbed. The downside is that IGBTs are not suitable for high frequency applications. Compared with MOSFET, the switching speed is slower and the turn-off time is longer.

In practical applications, the parameter requirements of inverter technology for IGBT are not static, and the requirements for IGBT are different.

Taken together, the following parameters are crucial in the selection of IGBTs.

One is the rated voltage, under the conditions of switch operation, the rated voltage of IGBT is usually higher than twice the DC bus voltage.

The second is the rated current, due to the load electrical start or acceleration, the current is overloaded, requiring that the IGBT can withstand 1.5 times the overcurrent in 1 minute.

The third is the switching speed.

The working state of IGBT has a great relationship with the forward grid voltage, the higher the voltage, the smaller the switching loss, and the smaller the forward voltage drop.

IGBT and MOSFET in new energy vehicles

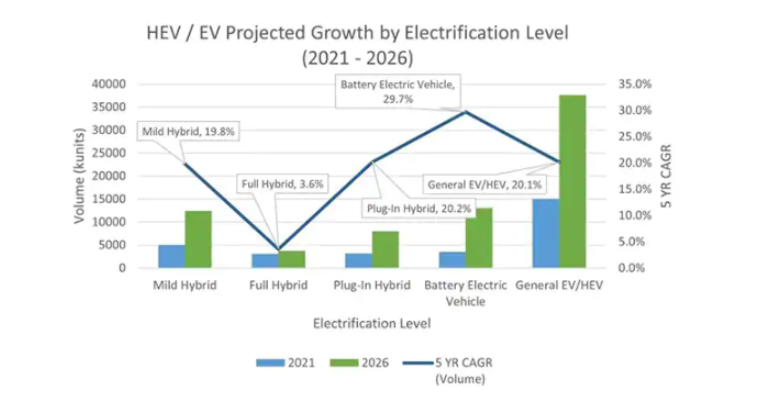

The electrification of cars is the trend of The Times. Now that governments have set their own carbon peak and carbon neutral targets, the shift from traditional ICE vehicles to pure electric vehicles is very important. Stricter global CO2 emission requirements continue to accelerate the process of vehicle electrification, with the compound annual growth rate (CAGR(VOL) of electric/hybrid (EV/HEV) vehicles expected to reach 20.1% from 2021 to 2026, battery electric vehicles (BEVs), known as zero emission vehicles (ZEVs), and electric vehicles. Its CAGR (VOL) will be as high as 29.7%.

Figure 2: EV/HEV growth over the next 5 years

The motor control system, engine control system and body control system in new energy vehicles all need to use a large number of semiconductor power devices, and its popularity has opened a window for the growth of the automotive power semiconductor market. Among all types of semiconductor power devices, the strongest future growth products will be MOSFET and IGBT modules.

According to the analysis results of research institute IC Insights, in 2016, the global MOSFET market size reached 6.2 billion US dollars, and the MOSFET market is expected to grow at a compound annual growth rate of 3.4% between 2016 and 2022. The global MOSFET market is expected to reach nearly $7.5 billion by 2022.

IGBT is the core device of the high voltage system of new energy vehicles, and its core application is the main drive inverter, in addition to the on-board charger (OBC), battery management system, on-board air conditioning control system, steering and other high voltage auxiliary systems. IGBT is also widely used in DC and AC charging piles. In new energy vehicles, MOSFETs are mainly used in low-voltage automotive appliances, such as electric seat adjustment, battery circuit protection, DC motors for wipers, and LED lighting systems.

IGBT and MOSFET "core" products recommended

AFGHL25T120RHD is onsemi's automotive grade, low-cost 1200V 25A IGBT, compliant with AEC Q101 and featuring a robust and cost-effective field Resistance II trench construction. Delivers excellent performance in demanding switching applications while providing low on-voltage and minimal switching losses for EV/HEV PTC heaters, electric compressors, on-board chargers and other systems.

On's other MOSFET module, the FAM65CR51ADZ1, is a 650V power integration module (PIM) with a boost converter, which is mainly used in the on-board charger (OBC) in EV/HEV, allowing the system to be designed to be smaller, more efficient and more reliable.

Infineon Technologies has an extremely rich portfolio of IGBT power modules with different circuit structures, chip configurations and current and voltage levels, covering most applications on the market. They are available in chopper, DUAL, PIM, four-cell, six-cell, twelve-cell, three-level, booster or single-switch configurations with current classes ranging from 6A to 3600A. The applicable power of IGBT modules is as small as a few hundred watts and as high as several megawatts.

Infineon's HybridPACK family, for example, offers several versions in six different packages, optimized for different inverter performance levels between 100kW and 200kW, extending the power range of IGBT modules for EV/ HEVs. The HybridPACK Drive in the family is a very compact power module optimized for EV/HEV vehicle traction applications with a power range of 100kW to 175kW for maximum efficiency in the actual drive cycle of an electric vehicle, reliably operating the inverter even in harsh environmental conditions.

Among them, HybridPACK Drive Flat module (FS660R08A6P2Fx) and Wave module (FS770R08A6P2x) are low-performance products in the HybridPACK Drive family of products. They are suitable for 100kW to 150kW inverters. As a high-end product in the portfolio, the HybridPACK Drive Performance module (FS950R08A6P2B) is targeted at 200kW inverters. Due to the use of special ceramic materials, and very useful alumina, its heat dissipation performance is improved by more than 20%, which can achieve higher current tolerance.

Infineon's 600V, 650V and 800V N-channel power MOSFETs are aimed at high-performance automotive applications, and CoolMOS N-channel MOSFETs are the company's representative product family for low to high power applications, with a smart balance between ease of use, high performance and price.

Conclusion

Power semiconductor devices, also known as power electronic devices, are the core devices of power electronic devices to realize electric energy conversion and circuit control. The silicon-based MOSFET developed in the 1980s has a working frequency of megabHz. With the advent of silicon-based IGBTs, power devices have found a solution between high power and high frequency.

In switching applications such as uninterruptible power supplies (UPS), industrial inverters, power control, motor drives, pulse width modulation (PWM), and switching power supplies (SMPS), MOSFETs and IGBTs are significantly superior to other switching devices in performance because of their superior characteristics. Among them, MOSFETs are mainly used for lower voltage and power systems, while IGBTs are more suitable for higher voltage and power applications.

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.